Best Sight Flow Indicators

Types of Sight Flow Indicator

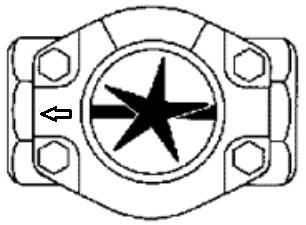

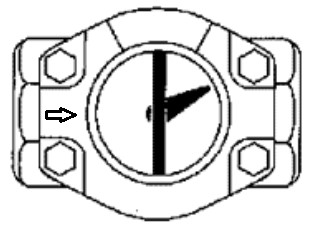

Rotary Type

Ball Type Sight Flow Indicator (BSF)

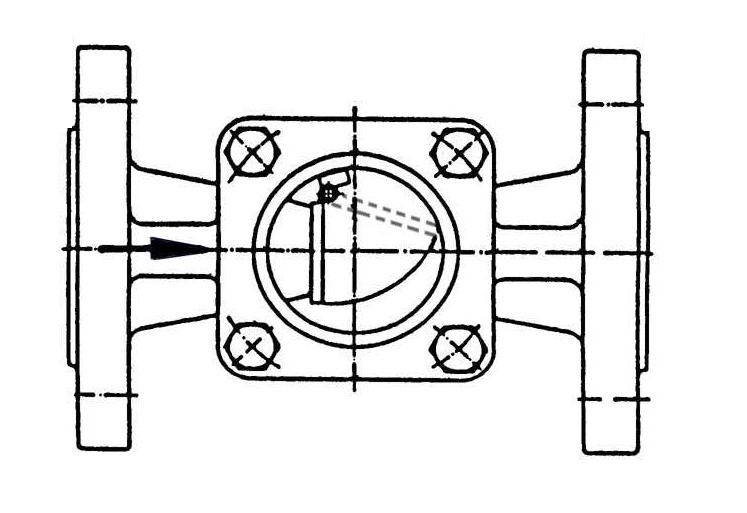

Propeller Type Sight Flow Indicator (PSF)

Fixed Flap Sight Flow Indicator (FFSF)

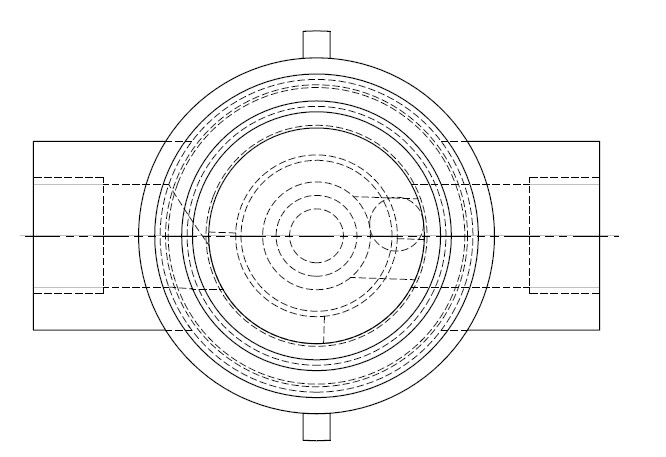

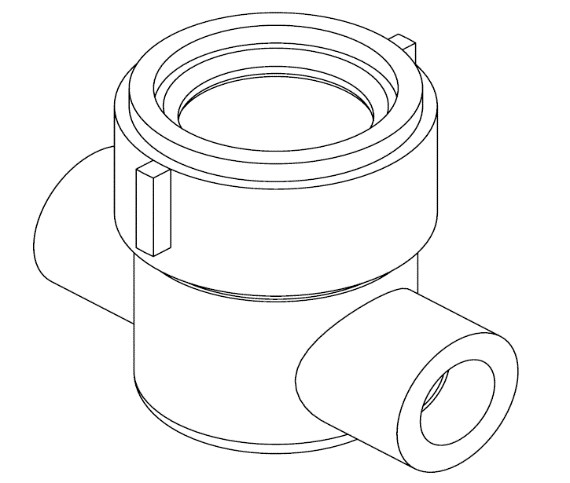

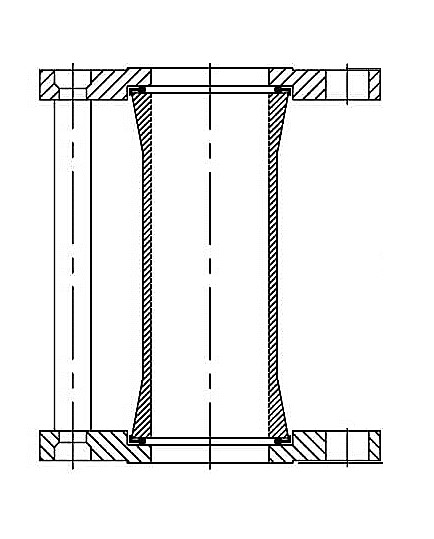

Full View Sight Flow Indicators (FVSF)

Fixed Flap Sight Flow Indicator (FFSF)

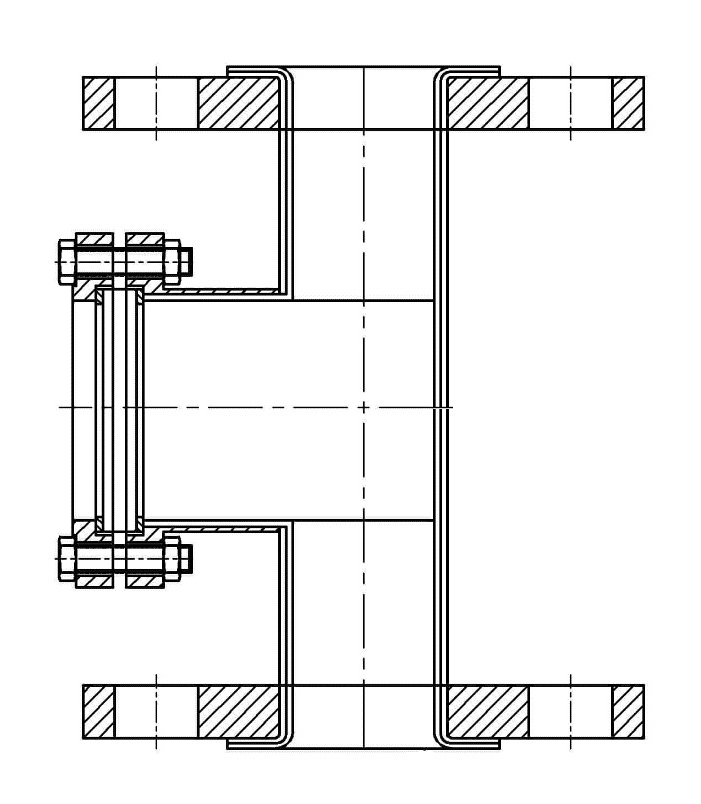

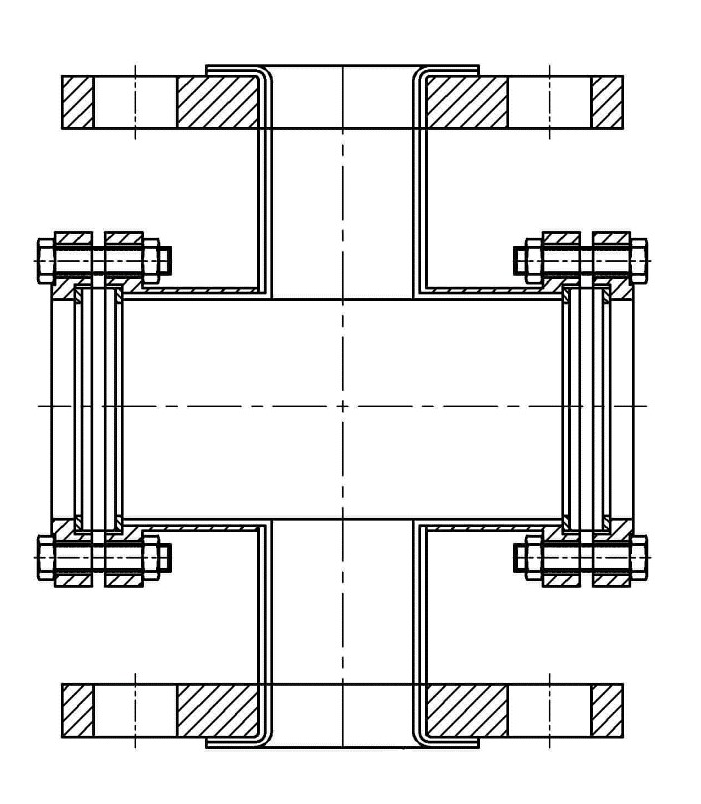

Double Window Sight Flow Indicator (DWSF)

Warning

Under corrosive conditions, the elements in condensate can affect the inside faces of the window(s), particularly where caustic alkali and hydrofluoric acid are present. It is recommended to check the sight glasses periodically for thinning of the window(s). If there is evidence of thinning or erosion damage then the window(s) should be replaced immediately. Always wear eye protection when viewing the contents of the sight glass.

Installation and maintenance note:

Disposal:

Technical Data Table

Model | BSF / PSF / FSF | FFSF | FVSF | WSF |

Material of Composition | Cast Steel / CF3M / CF8M | CS/SS/Bronze | CS / SS | CS / SS / Brass / Bronze |

Connection | BW/ NPT / Flanged | Flanged | Flanged | Flanged |

Maximum Pressure | 60 bar(g) / 870 PSI | 32 bar(g) / 464 PSI | 20 bar(g) / 290 PSI | 28 bar(g) / 405 PSI |

Maximum Temperature | 2000 C | 2000 C | 3000 C | 4000 C |

Stock Availability | Ready Stocks | NA | Ready Stocks | NA |

Data in the table are subject to change, please confirm with GAD for complete actuals details. | ||||