Best Emergency Relief Valve

EE-ERV-V18 series pressure relief and vacuum relief portfolio provides a complete range of standard and customized solutions, whatever demand you have protection of your assets from Pressure and Vacuum. ENVERDANT is an industry leader in Emergency Relief valve technology. A single point provider, we offer an extensive product range for reliable performance with lower valve life-cycle costs and unique solutions. Our unmatched technical expertise provides you with the pressure management products, application solutions and services that will positively impact your business.

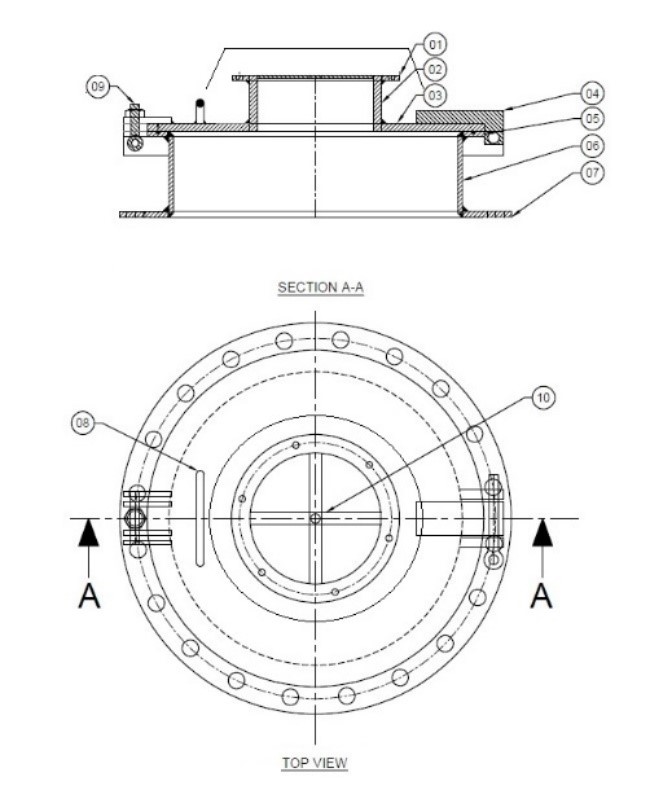

With the highly developed Technology and our continues improvement practice, the valves we manufacture are helping to maintain the tanks exact pressure or vacuum set limit and ensuring the precise safety of equipment / asset. This feature is achieved by valve seats made of stainless steel with precisely machined groves where an O-ring seals and locks the pressure or vacuum to reach until the set value, a precisely lapped valve pallet, as well as a reinforced housing design. After the excess pressure is relieved, the valve cover reseats and provides a tight seal again. It is primarily used as a safety device for emergency pressure relief for Equipment like storage tanks, containers, silos, and process engineering equipment; it offers reliable protection against overpressure and prevents impermissible product vapor loss close to the set pressure. Designed to relief particularly large amounts to prevent the tank from rupturing in an emergency case.

Normative Reference

- API STANDARD 520 – Part I (2008), Sizing, Selection and Installation of Pressure-relieving Devices in Refineries – Sizing and selection

- API RECOMMENDED PRACTICE 520 – Part II (2003), Sizing, Selection and Installation of Pressure-relieving Devices in Refineries – Installation

- API STANDARD 526 (2009), Flanged Steel Pressure-relief Valves

- API STANDARD 527 (1991), Seat tightness of Pressure-relief Valves

- ISO 4126-1 (2004), Safety devices for protection against excessive pressure – Safety valves

- ISO 4126-7 (2004), Safety devices for protection against excessive pressure – Common data

- ISO 4126-9 (2008), Safety devices for protection against excessive pressure – Application and installation of safety devices excluding standalone bursting disc safety devices

- ISO-WD 4126-11 (2011), Safety devices for protection against excessive pressure – Performance testing

Why an ERV

- Provides emergency pressure relief in case of a storage tank High pressure that is not immediately relivable by other instruments installed or other abnormal pressure conditions.

- Due to the abnormal rise in temperature, this emergency vent allows for required venting capacity, preventing tank deformation.

- Prevents tank from rupturing due to overpressure

- Operates when relief capacity exceeds normal vent capacity.

- It is Available in pressure/vacuum and pressure only configurations.

- Larger sizes also permit access into the tank.

- Wide variety of materials available.

Special Features and Advantages

- ASME Sec. VIII for Design of Pressure Devices and over pressure

- API STANDARD 520 – Part I (2008) & PART (2003), Sizing, Selection, Installation, Operation and Maintenance of Pressure Reliving Devices in Refineries – Sizing and Selection

- API STANDARD 526 (2009) – Flanged Steel Pressure Relief Valves

- API STANDARD 527 (1991) – Seat Tightness of Pressure Relief Valves

- ISO 4126-1 (2004), Safety Devices for Protection against excessive pressure – Safety Valves

- ISO 4126-7 (2004), Safety Devices for Protection against excessive pressure – Common Data

- ISO 4126-9 (2009), Safety Devices for Protection against excessive pressure – Application and Installation of Safety devices excluding stand-alone bursting disc safety devices

- ISO-WD 4126-11 (2011), Safety devices for protection against excessive pressure – Performance Testing

Features and Benefits

- Hinged vent system can be manually lifted allowing access to the tank for cleaning and inspection.

- Wide range of pressure settings to provide maximum tank protection whilst ensuring minimum product vapour loss.

- Long Life and Integrated Flame Arrestor Design

- Low-cost maintenance.

- Customizable Material and wide range of sizing allows our ERV to suit diverse applications.

- Minimal Dead Weight Pallet Chattering

In addition to the normal venting capacity provided by ENVERDANT’s ERV Vents and/or Flame Arresters, every large above ground flammable liquid storage tank should be provided with some means of relieving excessive internal pressure caused by exposure of the tank to a fire. Depending upon the strength of the tank structure, a vent sized to handle the normal venting requirements (for day-to-day operations) may be inadequate to handle the abnormal vapor efflux generated by heat from an exposure fire.

ERV-V1801: Spring Loaded

- Connection Sizes Available : 12IN to 24IN

- Operation : Spring

- Set Pressure : 0.01 Bar(g) to 1.20 bar(g)

- Set Vacuum (optional) : -0.01 Bar(g) to -0.25 bar(g)

- Connections Available : Flanges ANSI

- Material : CS / SS

- Temperature Range : 15⁰ C to 200⁰ C

- Applications : High Pressure Application and Vacuum Application

ERV-V1802: Weight Loaded

- Connection Sizes Available : 6IN to 28IN

- Operation : Weight

- Set Pressure : 0.01 Bar(g) to 0.16 bar(g)

- Set Vacuum (optional) : -0.01 Bar(g) to -0.20 bar(g)

- Connections Available : Flanges ANSI

- Material : CS

- Temperature Range : 15⁰ C to 320⁰ C

- Applications : Low Pressure Application and Low Vacuum Application

ERV-V1803: Pedal / Lever Loaded

- Connection Sizes Available : 16IN to 24IN

- Operation : Pedal / Lever

- Set Pressure : 0.03 Bar(g) to 0.26 bar(g)

- Set Vacuum (optional) : -0.01 Bar(g) to -0.18 bar(g)

- Connections Available : Flanges ANSI

- Material : CS / SS / Alloy Steel

- Temperature Range : 10⁰ C to 200⁰ C

- Applications : High Pressure Application and Vacuum Application

ERV-V1804: Bleeding Vent

- Connection Sizes Available : 24IN

- Operation : Self

- Set Pressure : 0.01 Bar(g) to 0.40 bar(g)

- Set Vacuum (optional) : -0.01 Bar(g) to -0.30 bar(g)

- Connections Available : Flanges ANSI

- Material : CS / SS

- Temperature Range : 30⁰ C to 80⁰ C

- Applications : Very Low Pressure Application and Very Low Vacuum Application