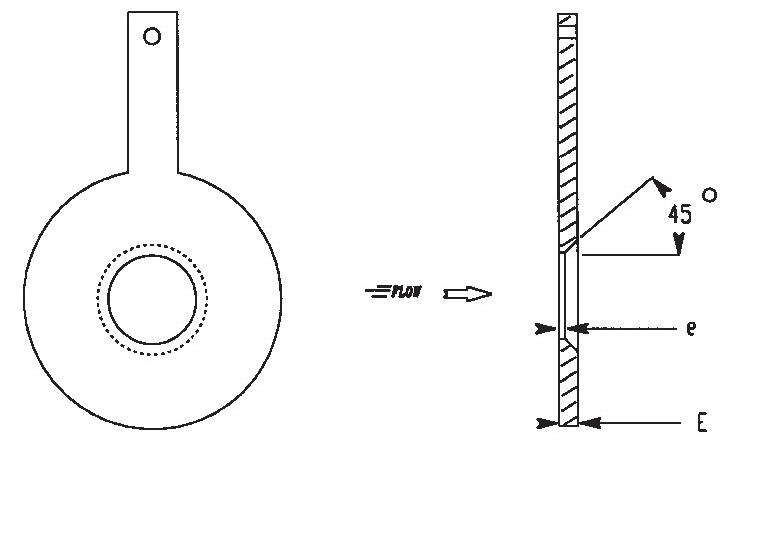

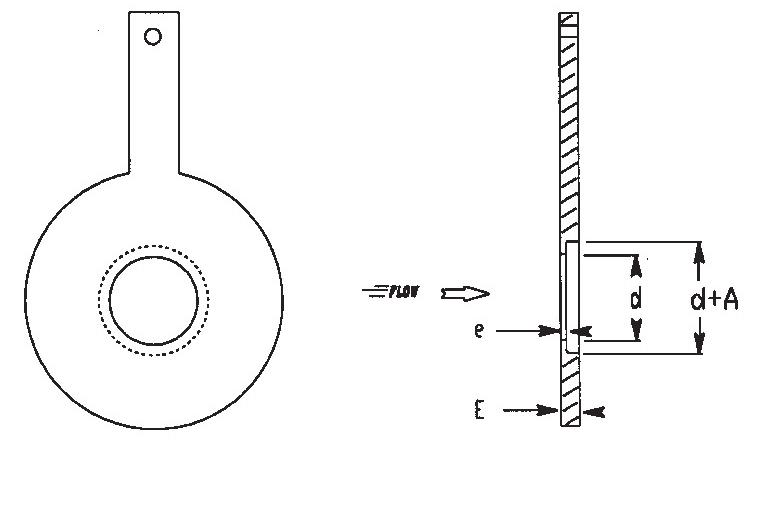

ORP-V19 series are differential pressure primary devices used to produce a fluid restriction in a pipeline. The differential pressure across the orifice plate is proportional to the square of the fluid velocity. Orifice plates are used in a wide range of pipe sizes from small to large diameters and are effective in both low- and high-pressure services.

The bore diameter can be calculated by our engineering department or specified by the customer. The handles and the plates are machined to meet the specified finish. The standard material for an orifice plate is usually 316 Stainless Steel, but a variety of other materials such as 304 Stainless Steel, Monel and Titanium are also available for special applications.

| Standard sizes | : 1” to 24” |

| Hydrostatic Test | Hydrostatic Test (1.5 x design pressure for 10 minutes) |

| Plate / Flanges | 1-) Carbon steel 2-) Stainless steel AISI 316 –L or 304-L 3-) Customer Specification |

| Flange Tap Type | 1/2-in. NPT Flange Taps / 1/2-in. Socket Flange Taps |

| End Flange | : DIN Standards & ANSI Standards : Other Standards (on request) |

| Orifice Plate Sealing | Teflon, Silicon, EPDM, Synthetic Rubber, Graphite and others (Selected according to the service) |

| Chosen Plate Thickness | Depends on the line Size & Service Parameters |

Digitally Powered by Beta Digital Marketing