Best Pressure Vacuum Relief Valve

EE-BRV-T18 series valves are highly developed pressure and vacuum relief valves with excellent work efficiency. These valves are useful as relief valves for blanketed vessels in which fluids are filled & drawn at a certainengineered flow rate. This valve is installed in the in-and out breathing lines of tanks, vessels and process equipment to protect against unpredicted fluctuations in pressure & vacuum. By retaining toxic vapors and avoiding atmospheric contamination, these valves provide increased fire protection and safety.

Pressure cum vacuum relief breather valves are designed to protect tanks from possible hazards due to over pressure created by thermal expansion and product movement into the tank and excessive vacuum created by thermal contraction and product movement out of the tank. At the same time it minimizes costly product evaporation / loss. Continued design improvements of these valves provide high efficiency, maximum flow capacity and minimum leakage.

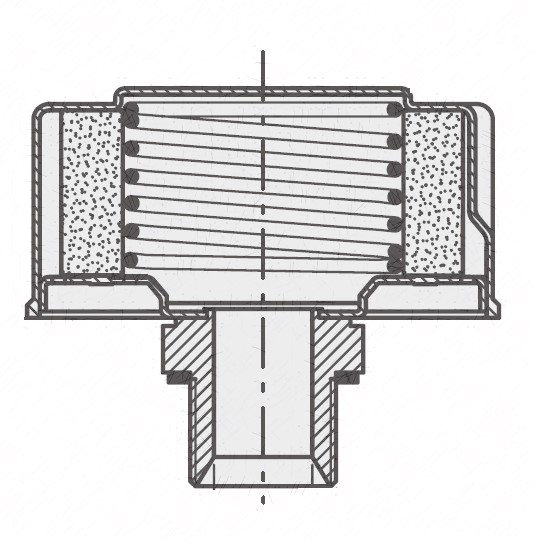

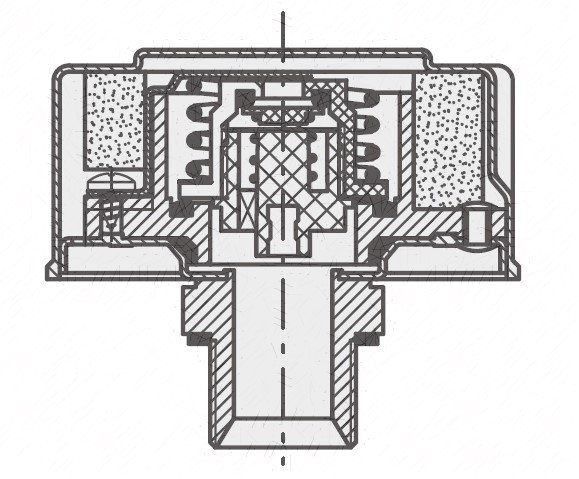

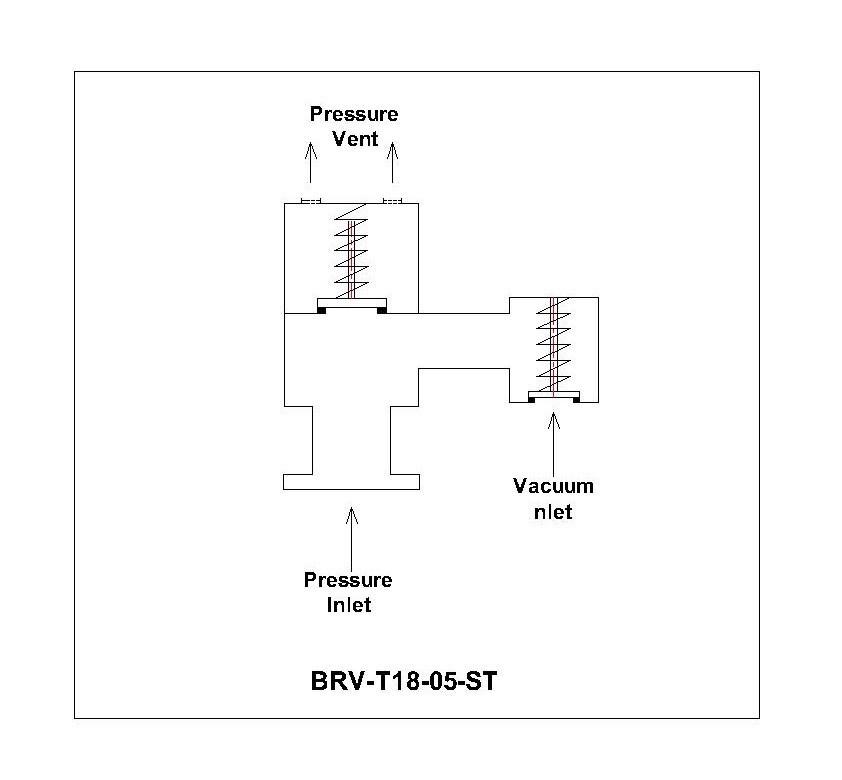

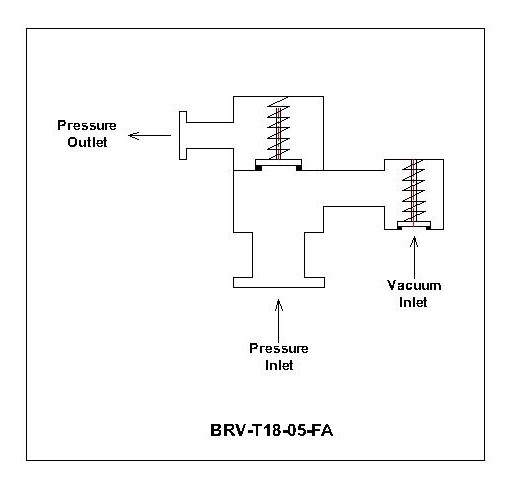

Industrial Breather Valve (FA/LP/HP)

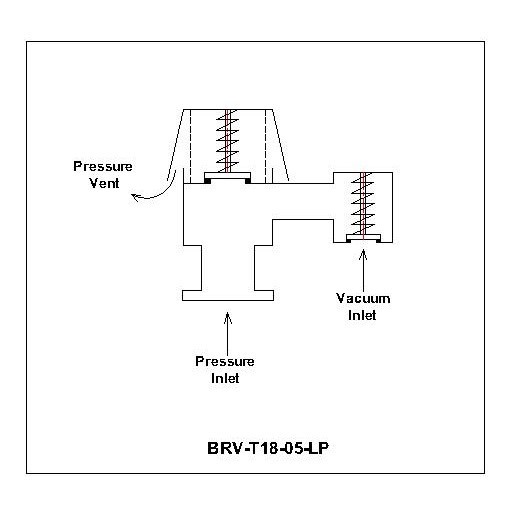

BRV-T18-05-LP

- In case of Flammable Gas release from this BRV, the pressure outlet is designed with flanged connection so that it can be adopted with a flame arrester (Model: BRV-T18-05-FA).

BRV-T18-05-LP

- In case of Gas release from this BRV is inflammable and at low pressure (less than 3 Kg/cm2), the pressure outlet is designed with dished vent (Model: BRV-T18-05-LP).

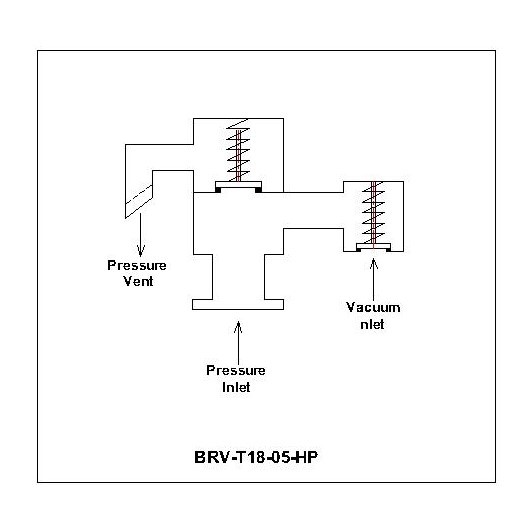

BRV-T18-05-LP

- In case of Gas release from this BRV is inflammable and at high pressure (more than 3 Kg/cm2), the pressure outlet is designed with inverted vent to avoid pressure hazards (Model: BRV-T18-05-HP).

- Depending on the application of pressure inlet and hazardous condition the outlet can be designed. While the inlet size depends on the design flow rate of gas and the vacuum disk is sized as per the draining flow rate of tank or vessel.

Technical Data Table

| Model | BRV-T18-05-XX-L | BRV-T18-05-XX-H |

| Application | Low Temperature & Non Corrosive | High Temperature & High Corrosive |

| Material of Composition | Carbon Steel | Stainless Steel |

| Body | Carbon Steel / Cast Iron ASTM A516 Gr.70 / A216 WCB | SS 304 / SS316 / SS304 L/SS316L A351 Gr.CF8, Gr.CF8M/Gr.CF3,Gr. CF3M |

| Flange | Carbon Steel / Cast Iron | SS 304 / SS316 |

| Spring | Carbon Steel / Cast Iron | SS 304 / SS316 |

| Guide Rod | Carbon Steel / Cast Iron | SS 304 / SS316 |

| Cap | Carbon Steel / Cast Iron | SS 304 / SS316 / SS304 L/SS316L |

| Seal / Gasket | NAF / PTFE | SPW /FEP |

| Design Pressure | Varies | Varies |

| Design Temperature | 120 Deg. C | 300 Deg. C |

| Inlet Set Pressure | Varies | Varies |

| Vacuum Set Pressure | Varies | Varies |

| Flow Rate | Varies (depending on Size) | Varies (depending on Size) |

| Data in the table are subject to change, please confirm with GAD for complete actuals details. | ||

EE-V18-BRV-T18-05-BC/ DB

MATERIAL

- Cover : Steel Sheet /CS / SS Sheet / AL

- Threaded connector: zinc-plated steel.

- Internals : CS / SS Sheet / AL

- Spring : CS / SS / Spring Steel

- Packings : NBR / PTFE / Teflon / Silicon

MAXIMUM WORKING TEMPERATURE 75 Deg C

FILTER : On request

FEATURES AND APPLICATIONS

- DWB creates a pressure plenum chamber right above the oil level within given limit conditions to avoid any reservoir deformation.

ADVANTAGES

- It reduces reservoir air volume intake keeping clean fluid and filter.

- it improves suction pump action under working conditions reducing cavitation phenomenon.

- it prevents fluid leakage when the system is part of a mobile unit;

- it reduces foam in fluid.

*Material / Specifications / Dimensions shall be according to the requirements and shall be customized on request.

Container / Tank Breather Valve (BC/DB)